Disadvantages of Tubular Batteries: An Honest, In-Depth Reality Check

18 December 2025

Tubular batteries are often marketed as the best solution for inverter and UPS backup—and in many cases, that reputation is deserved. Their long life, deep-cycle strength, and reliability during extended power cuts make them a preferred choice across Indian homes, offices, and industries.

But let’s be clear: no battery technology is flawless.

If you’re investing your hard-earned money, you deserve a transparent breakdown—not marketing hype. This guide explores the real disadvantages of tubular batteries, the engineering reasons behind them, how they affect actual day-to-day usage, and how advanced manufacturers like Lento Industries Pvt. Ltd. actively reduce these limitations.

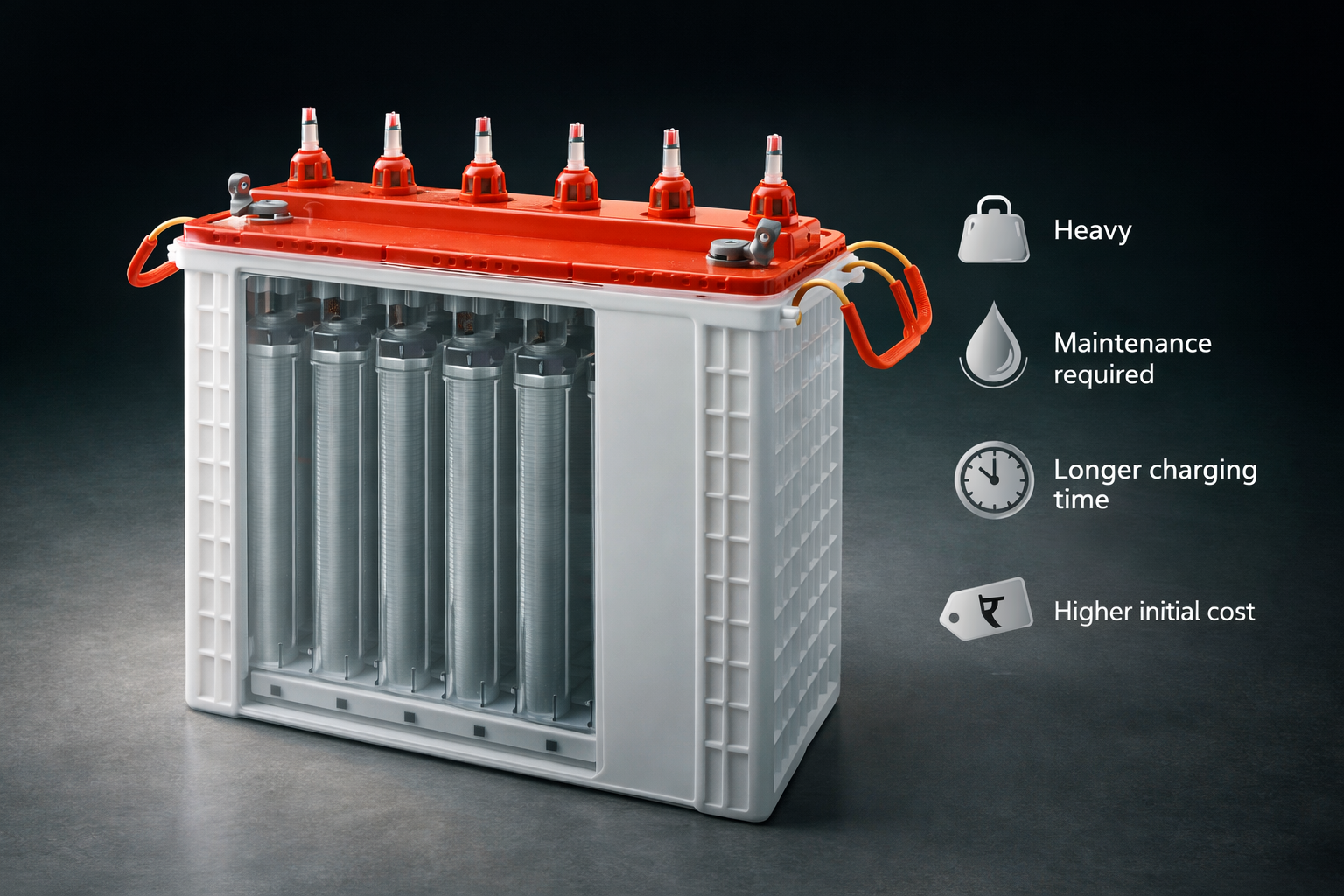

1. Higher Initial Cost Than Flat Plate Batteries

Why this feels like a drawback

Tubular batteries typically cost 15–30% more upfront than flat plate or local lead-acid batteries, making them appear expensive at first glance.

The technical reason

This higher price is not arbitrary. Tubular batteries use:

-

Positive tubular plate technology

-

Higher lead content per Ah

-

Stronger spine alloys

-

Thicker separators and reinforced grids

All of this increases material and manufacturing costs.

Real-world impact

First-time buyers or budget-conscious households may hesitate due to the higher entry price.

The honest reality

Over time, tubular batteries:

-

Last 2–3 years longer

-

Deliver more charge–discharge cycles

-

Maintain capacity better under heavy loads

Cost per year of usage is actually lower, making tubular batteries more economical in the long run.

2. Heavier Weight and Larger Physical Size

Why it’s inconvenient

Tubular batteries are:

-

Significantly heavier

-

Physically bulkier

-

Space-demanding

A standard 150Ah tubular battery weighs 55–65 kg, which is not easy to handle.

Engineering explanation

The weight comes from:

-

Dense lead plates

-

Thick tubular construction

-

Larger electrolyte volume for deep cycling

Practical issues users face

-

Difficult to move without help

-

Unsuitable for wall mounting

-

Needs a strong, ventilated floor space

Can this be avoided?

Not really—but proper installation planning solves the problem permanently.

3. Regular Water Topping (Flooded Tubular Batteries)

Why users dislike this

Most flooded tubular batteries require distilled water top-ups every 3–6 months.

The chemistry behind it

-

Electrolyte heats up during charging

-

Hydrogen and oxygen gases are released

-

Water gradually evaporates

This is normal behavior for flooded lead-acid chemistry.

What happens if ignored

-

Plates get exposed

-

Sulphation accelerates

-

Battery life reduces sharply

How modern designs reduce this

High-quality batteries—such as those from Lento Industries Pvt. Ltd.—use:

-

Low-antimony alloys

-

Optimized vent plugs

-

Clear water-level indicators

Result: Lower water loss and less frequent maintenance.

4. Longer Charging Time Compared to Flat Plate Batteries

Why it matters

Tubular batteries charge slower, especially when deeply discharged.

Technical reason

-

Thicker plates absorb charge gradually

-

Designed for deep cycling, not quick bursts

-

Higher electrolyte density slows charging rate

Real-world impact

In areas with:

-

Short power availability windows

-

Frequent interruptions

the battery may not always reach 100% charge.

The fix

This issue largely disappears when:

-

Correct inverter charging current is used

-

Full charge cycles are allowed periodically

5. Overkill for Very Short Backup Needs

Why it can be unnecessary

If your power cuts are:

-

Rare

-

Short (30–60 minutes)

a tubular battery may be over-engineered for your needs.

Better alternatives in such cases

-

SMF batteries (maintenance-free)

-

Lithium-ion batteries (compact and fast charging)

Tubular batteries shine where long, frequent outages are the norm.

6. Sensitive to Poor Charging Quality

Why this is a serious concern

Tubular batteries demand:

-

Accurate charging voltage

-

Controlled current flow

Cheap or mismatched inverters can cause:

-

Undercharging → sulphation

-

Overcharging → overheating and water loss

Real-world consequence

Even the best tubular battery will fail early if paired with:

-

Low-quality inverter

-

Incorrect VA–Ah matching

Expert recommendation

Always use:

-

High-efficiency inverter

-

Proper battery capacity calculation

7. Initial Break-In Period Before Peak Performance

What surprises users

New tubular batteries need 10–15 charge–discharge cycles to reach full capacity.

Why this happens

-

Electrochemical formation stabilizes gradually

-

Active material utilization improves with use

User perception

Backup may feel slightly lower in the first few weeks.

Truth

This is normal, temporary, and not a defect.

Are These Disadvantages Deal-Breakers?

For most Indian households and businesses—absolutely not.

These limitations are:

-

Well-understood

-

Manageable

-

Heavily outweighed by durability and reliability

How Lento Industries Pvt. Ltd. Minimizes Tubular Battery Drawbacks

Lento Industries Pvt. Ltd. focuses on engineering refinement, not just capacity numbers:

-

Optimized tubular plate geometry

-

High-purity lead for better conductivity

-

Low water-loss design

-

Stable voltage under fan, TV, and appliance load

-

Longer cycle life with reduced maintenance

The result is a battery that feels easier to own, not harder.

When Tubular Batteries May NOT Be the Right Choice

You should reconsider tubular batteries if:

-

Installation space is extremely limited

-

You want zero-maintenance operation

-

Backup requirement is minimal

-

Budget is severely constrained

In these cases, SMF or lithium batteries make more sense.

Why Our Tubular Battery Still Stands Out

Yes, tubular batteries have limitations — and we don’t hide them. But what truly matters is how well a battery is engineered to handle those limitations.

Our tubular batteries are built with a clear focus on real Indian power conditions, not lab-only promises.

What sets our tubular battery apart is the balance it strikes between strength, efficiency, and practicality:

-

Heavy-duty tubular plates designed for long power cuts, not short demonstrations

-

High-purity lead composition that ensures stable voltage and faster charge acceptance

-

Optimized electrolyte formulation to reduce water loss and maintenance stress

-

Strong casing and internal structure that withstands heat, load fluctuations, and daily wear

-

Consistent backup performance even under fan, TV, and appliance-heavy usage

While cheaper batteries compromise on material quality to reduce price, our tubular battery focuses on long-term reliability, fewer replacements, and predictable performance year after year.

In simple words:

It doesn’t just survive power cuts — it’s built for them.

If you’re looking for a tubular battery that delivers what it promises, performs honestly in real conditions, and gives you true value over time, our tubular battery remains a dependable choice.

Final Verdict: Are Tubular Batteries Worth It?

Yes—when chosen correctly.

Despite a few disadvantages, tubular batteries remain:

-

The most reliable solution for long outages

-

The best long-term value in Indian conditions

-

A proven technology trusted for decades

A well-designed tubular battery from Lento Industries Pvt. Ltd., paired with the right inverter and basic care, delivers years of dependable backup with minimal compromise.